Blog

Miter Saw: Precision and Innovation in Modern Craftsmanship

Discovering the Precision of a Miter Saw

The Miter Saw stands as a cornerstone in the world of woodworking tools, offering unmatched precision for angled cuts that bring projects to life. Whether you’re crafting intricate trim work or framing sturdy structures, this versatile tool transforms raw materials into polished masterpieces. As a Miter Saw manufacturer, we pride ourselves on engineering equipment that blends innovation with reliability, ensuring every cut aligns perfectly with your vision.

Exploring Miter Saw Production Excellence

Delving into Miter Saw production reveals a meticulous process where quality materials meet advanced engineering. From forging the robust base to integrating laser guidance systems, each step in the Miter Saw production process prioritizes durability and user safety. Our facilities, operating as a premier Miter Saw factory, employ state-of-the-art techniques to produce models like the 254mm 1800W Miter Saw factory edition, which delivers 1800 watts of power for seamless performance in demanding environments.

The Role of a Reliable Miter Saw Supplier

Choosing the right Miter Saw supplier can elevate your toolkit from ordinary to exceptional. We serve as a trusted Miter Saw supplier, providing not just products but comprehensive support for woodworking enthusiasts and professionals alike. Our inventory includes a range of Miter Saw tools designed for versatility, featuring ergonomic handles and LED lighting to enhance visibility and reduce fatigue during extended sessions.

Understanding the Miter Saw Production Process

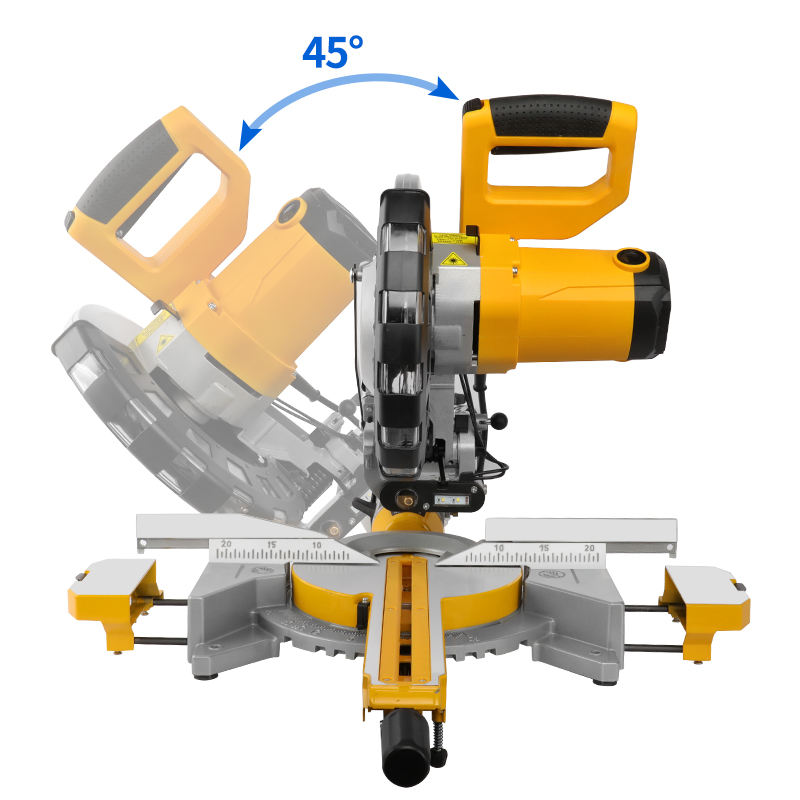

The Miter Saw production process begins with selecting high-grade alloys for the frame, ensuring stability under heavy loads. Precision machining crafts the bevel adjustments, allowing for exact 45-degree angles essential in construction and carpentry. In our Miter Saw factory, quality checks are rigorous, from testing the laser system for pinpoint accuracy to verifying the dust collection mechanisms that keep workspaces clean. This attention to detail in Miter Saw production guarantees tools that withstand rigorous use while delivering clean, effortless cuts.

Innovations from Woodworking Tools Manufacturers

As leading Woodworking tools manufacturers, we integrate cutting-edge features into every Miter Saw, such as adjustable fences and intuitive angle scales. The 254mm 1800W Miter Saw factory model exemplifies this, with its compact yet powerful design suited for both DIY projects and professional workshops. Our commitment shines through in the rubberized grips and secure clamps, fostering control and confidence for users tackling everything from crown molding to baseboards.

Why Partner with a Miter Saw Manufacturer

Partnering with a dedicated Miter Saw manufacturer means accessing tools built for longevity and efficiency. Our Miter Saw tools feature multi-functional capabilities, including bevel and miter adjustments that simplify complex angles. In the Miter Saw production process, we emphasize ergonomic design, resulting in lighter frames that enhance portability without sacrificing power. For those seeking a Miter Saw supplier, our offerings ensure seamless integration into any workflow, boosting productivity and precision.

Elevating Your Craft with Miter Saw Tools

Miter Saw tools continue to evolve, incorporating LED illumination and laser guides to minimize errors and shadows in low-light conditions. As a Miter Saw factory, we focus on creating products like the innovative compound models that redefine versatility. The detailed miter scales and robust bases support a variety of materials, making them indispensable for Woodworking tools manufacturers and end-users alike. Whether in a bustling workshop or a home garage, these tools empower creators to achieve professional-grade results with ease.

This exploration of the Miter Saw highlights its pivotal role in modern craftsmanship. With ongoing advancements in Miter Saw production, the future promises even greater efficiency and accuracy, inviting woodworkers to push the boundaries of their projects.