Bestseller Product

A client that's unhappy for a reason is a problem, a client.

Related Products

Accept that it’s sometimes okay to focus just on the content.

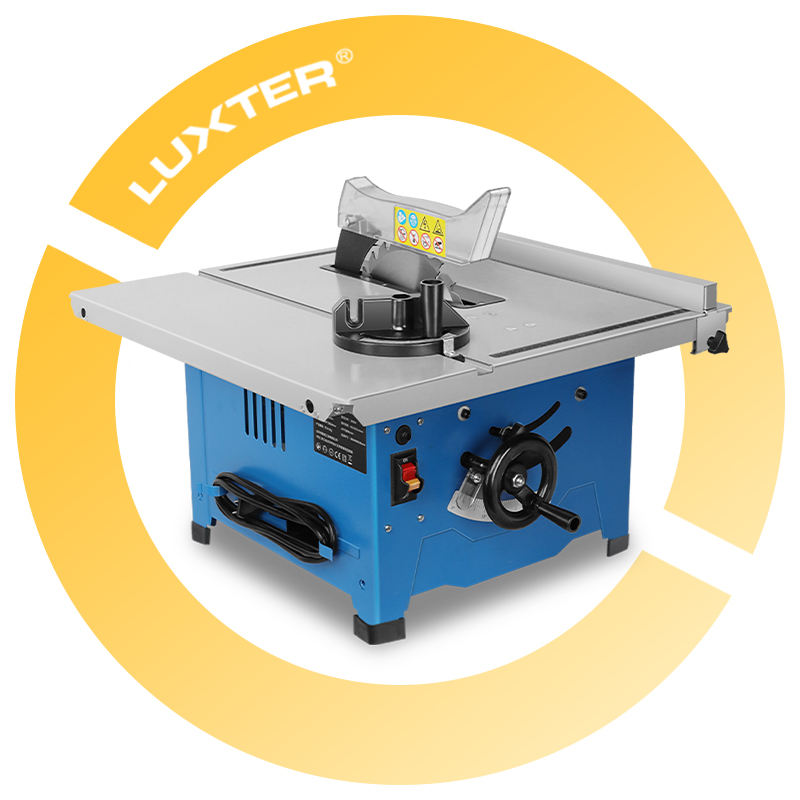

TOOL & EQUIPMENT

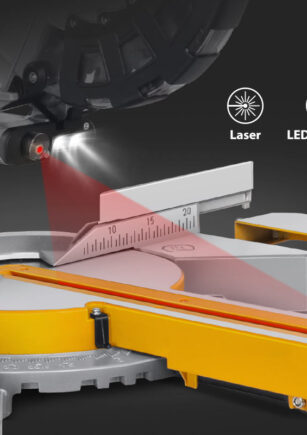

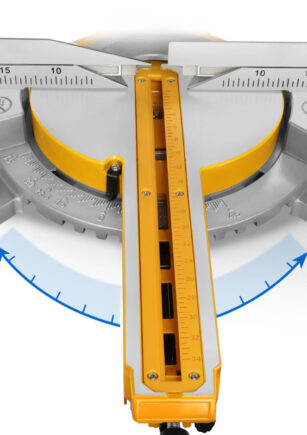

How Choose Equipment & Tool

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template.

Our Articles

Assumptions and potentially serious design.